Total Energy Optimization

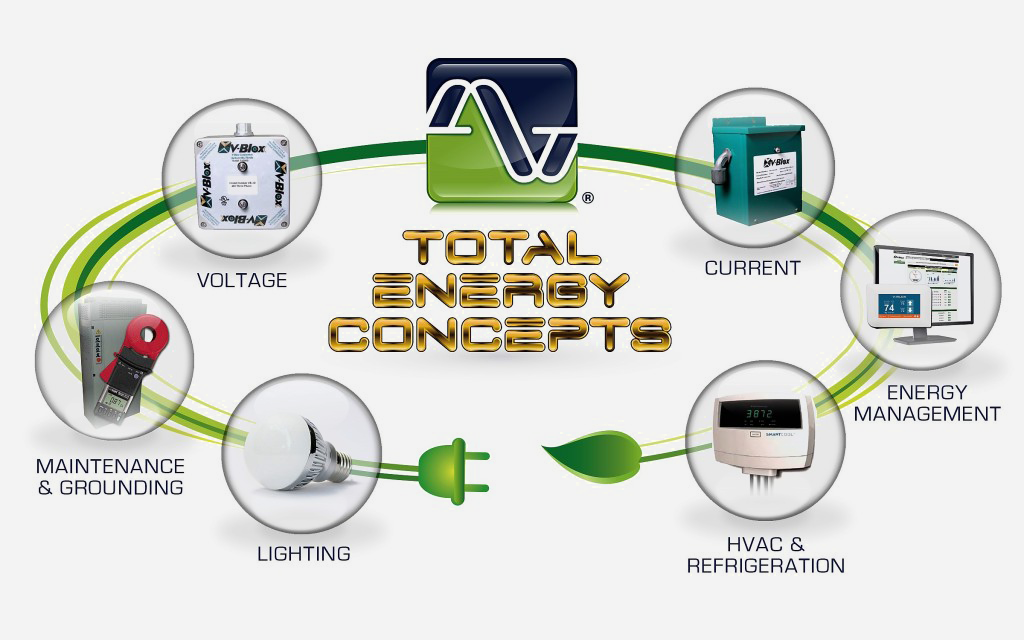

In today’s business world, bottom line profitability is everything and reducing expenses is easier than increasing sales to help improve that bottom line. Total Energy Concepts employs a systematic approach to optimizing your electrical system to help reduce your energy bills and reduce monthly expenses.

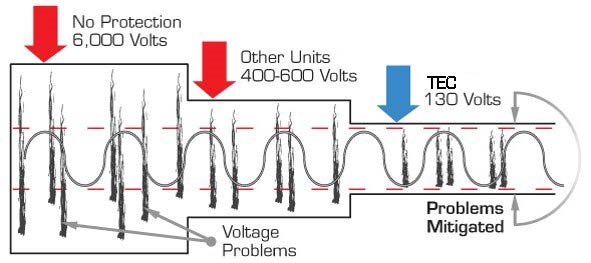

Clean Voltage

Your electrical system starts with something, and that something is the VOLTAGE. Voltage equals pressure, and if we attribute that pressure to blood pressure, you can see how having Clean, Optimized Voltage will allow your facility to operate more efficiently, which will also result in reduced maintenance and downtime expenses. 90-95% of equipment problems are caused by Voltage issues that originate within your electrical system, not the utility company. The TEC VCU Units ensure your electrical system is optimized and protected, and offers the following additional benefits:

- Complete Umbrella of Facility Protection

- Increased Life of Electrical Equipment

- Facility Wide Voltage Stability and Optimization

- Industries FASTEST Clamping Speed

- Industries FASTEST Recovery Time

- $5,000 Connected Equipment Guarantee per Unit

- Decreased Maintenance and Downtime Costs

- Decreased Equipment Operating Temperatures

- Reduced Energy Consumption

- Industries LOWEST Clamping Level

- 10 Year Product Warranty

- Peace of Mind……

Optimized Current

The other item that makes up the electricity equipment needs to operate is AMPERAGE or CURRENT. If we use the same analogy as the Voltage, the CURRENT would be like your internal organs. Electrical equipment, like internal organs, depend on a clean, efficient distribution system for them to function properly. What we are talking about in the electrical world is Power Factor and it is a measurement of the efficiency of the distribution system that is supplying the electricity to the equipment. A poor Power Factor is like having clogged arteries and veins in your body. When you apply Power Factor Correction at the electrical load connection points, it optimizes the distribution system from that point back to the source of the power. Optimizing the flow of energy in this manner results in reduced energy consumption. The TEC PFC Units, when applied properly will ensure your electrical system is delivering nearly 100% efficient power to your equipment, and offers the following additional benefits:

- Nearly 100% Efficient Electrical Distribution System

- Increased Life of Electrical Equipment

- No More Utility Penalty Fees (For Penalized Customers)

- Custom Engineered for each Application

- Indicator Lights for Operation

- Manufactured and Built with High Quality Components

- Decreased Maintenance and Downtime Costs

- Decreased Equipment Operating Temperatures

- Reduced Energy Consumption

- Maintenance Free Operation

- Internal Circuit Breaker Protection

- Industries Best Warranties

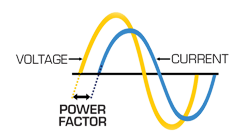

Power Factor is the difference between the Voltage and Current with the Current lagging behind the Voltage. Ideally, the Voltage and Current would look like the same line which means maximum efficiency and an almost Unity (100%) Power Factor.

SmartCool Technology

Air Conditioning is a MAJOR operating expense for every business. The SmartCool product can reduce these costs by saving energy on air conditioning and refrigeration systems without affecting the temperature or humidity of the air conditioned space. Working in conjunction with the existing thermostat or control systems, the SmartCool product takes over or learns the compressor cycle and determines when and for how long that compressor should run to MAXIMIZE the rate of heat removal (Cooling) by optimizing the compressor cycle.

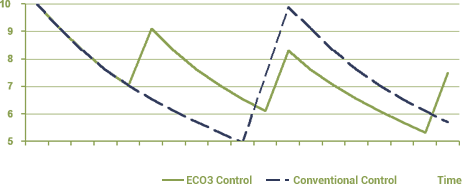

The diagram above illustrates the cycle of a compressor under a conventional control system…shown by the purple dashed line, and the same cycle under the SmartCool control…shown by the green line. You can see the SmartCool Unit dynamically adjusts the length of each operating cycle in order for the compressor to run at its optimum state with higher suction pressure where it is most energy efficient. By doing this…the SmartCool product can produce significant compressor run-time savings without affecting the temperature of the cooled space. The cooled space sees the same temperature satisfaction with a lot less compressor run time.

- Saves on Average 15-25% on Compressor Run-Time

- Ensures a More Efficient A/C or Refrigeration System

- Retrofits onto Existing A/C or Refrigeration Systems

- DOES NOT Affect Existing Manufacturer Warranties

- Automatic Fail Safe Controls

- Internal Data Logger Monitors Performance

Nano LiquiTec™ Technology

The American Society of Heating Refrigeration and Air Conditioning Engineers (ASHRAE) discovered a problem that affects all HVAC systems – Oil Fouling. It is known that 5-10% of the Compressor Oil travels throughout the refrigerant lines during the normal refrigeration process. Eventually, this oil starts to build up in the lines, like plaque does in your arteries and causes a loss of efficiency. Left untreated, the Oil Fouling will continue to accumulate during the life of the refrigeration system. ASHRAE has confirmed that the accumulation of oil in a system can degrade the performance of the refrigeration system as much as 30%, and in older systems, it can be as high as 40%. This means your equipment has to work harder, run longer, and consumes more energy.

Nano LiquiTec™ is a breakthrough synthetic catalyst with graphene and nanotechnology, engineered to create nano-convection for enhanced heat transfer to remove oil fouling and preserve precious energy.

Benefits of the Nano LiquiTec™ Product:

- Breakthrough Nano-Technology with Graphene Creates Nano-Convection to Enhance Heat Transfer to Remove Oil Fouling

- Reduces Friction, Noise, and Vibration

- Increases Lubricating Capability of Existing Oil

- 100% Non-Toxic Synthetic Catalyst

- DOES NOT Affect Existing Manufacturer Warranties

- Reduces Compressor Run Time = Energy Savings

- Is NOT a Polarized Refrigerant Oil Additive (PROA)

- Cools Space More Rapidly with Colder Vent Air

Award-Winning Technology — “Best Business Idea – 2017” — Forbes School of Business & Technology

View the Nano LiquiTec™ Cut Sheet (PDF) »

CUES Technology

It is estimated that 20% of the world’s global energy is used by Refrigeration. A Refrigeration System, such as a Walk-In Cooler or Freezer works in a series of cycles that measures air in and around the product it’s cooling and is done so by a traditional start/stop method designed to maintain a pre-set required space temperature. The problem with this type of system is the word “AIR”. The temperature probe or sensor is measuring the air temperature, when it should be measuring the product temperature. Air is the fastest to heat up and the fastest to cool down, so imagine a walk-in cooler for instance. The inside air temp is at say 38 degrees, and there is a thermostat and copper temperature probe inside the unit that is controlling that refrigeration system. Someone needs to open the unit and grab some product, so the door is opened, the product is grabbed, and the door then is shut with the total time of the process being roughly 10 seconds. The problem is, the warmer air that entered the cooler for that 10 seconds, made its way to the copper probe, the thermostat then realized a rise in temperature, so it turned on the compressor. Even though the temperature of the product did not change, the compressor was turned on due to a quick blast of warmer air and now will run for at least 4-6 minutes for nothing. Imagine how many of these scenarios have taken place in the past.

CUES is a simple device that fits over the thermostat probe or sensor in a walk-In Cooler or Freezer and is designed to mimic as if that temperature probe or sensor was placed into the food or product, versus measuring the air temperature. By providing the thermostat or control system with a simulated product temperature, not only is this a better way to control the temperature, but it results in less compressor run cycles due to the short warm air blasts not being able to reach the temperature probe or sensor, which ultimately saves energy! Also, a more accurate food/product temperature can be maintained with the CUES technology to ensure maximum freshness.

Benefits of the CUES Product:

- Reduced Refrigeration Run Cycles = Energy Savings

- Retrofits to any type of Control System

- Better Food/Product Temperature Control

- Increased Equipment Life Cycle

- Easy Installation with NO Downtime

- Reduced Defrost Cycles with Freezers

Demand Controlled Ventilation (DCV)

Ever facility by building code has to be ventilated properly, meaning fresh air has to be brought in to replenish the oxygen levels inside of a controlled space. Carbon Dioxide (CO2 ) is recognized as the method to measure and control the ventilation requirements in buildings. Per calculated building codes, the ventilation system is set based on an occupancy number, or how many people will be in a facility. The problem is, the ventilation settings are derived from a table and 90% of the time, the ventilation settings are set to over-ventilate the facility sending conditioned air back outside into the atmosphere, which essentially is a waste of energy. Imagine this, your facility has (10) Roof Top Air Conditioners. The Fresh Air Damper settings on those units are set to 100% wide open, meaning every time those units run, they are pulling the maximum amount of outside air possible. That is like having (10) holes in the roof of your facility. In the summer, the units would be pulling hot, outside air into the cooled space, which means all that air has to be cooled again….and vice versa for the winter.

The way to fix this problem is to incorporate a Demand Controlled Ventilation (DCV) system into the existing ventilation system. The DCV system would then control the fresh air dampers and bring in fresh air when needed, and simply recirculate the air when not. Typically, the cost to implement a DCV system was too high as the labor cost to run wires to sensors and control equipment was too high…..until now!

TEC has partnered with a company called AirTest that has developed and brought to the market a fully wireless DCV system that can be implemented into any existing HVAC system for a fraction of the cost. This offers significant energy savings by ventilating the facility based on the actual (CO2 ) levels in the space, and keeping in the conditioned air when applicable. Not only does this save energy, but it also ensures good indoor air quality for a comfortable and productive environment.

Key Benefits of the DCV System:

- Significant Energy Savings with Ventilation Based on Actual Occupancy

- Eliminate Costly Over Ventilation Issues

- Provides Greater Occupant Comfort and Productivity

- DCV Systems are a Recognized Measure to Obtain a LEED Green Building Rating

- Short Paybacks due to the Wireless Condition – Less Labor Costs to Install

- Real-Time Sensor Monitoring to verify Space Conditions

View the TEC DCV Cut Sheet (PDF) »

CoolPro EM Control Technology

It is estimated that at least 20% of HVAC costs could be eliminated by properly adjusting/setting existing thermostats that control HVAC units. The revolution of the “smart” thermostat has begun and is proving to be a valuable measure to take due to the significant reduction in energy consumption being seen.

TEC has partnered with V-Blox to offer the CoolPro EM System, which replaces the standard thermostat control systems and offers 100% control of the HVAC system at your fingertips. We took the technology one step farther and also offer Energy Monitoring as part of the system, where the energy consumption of a single piece of equipment or an entire facility can be monitored as part of the solution. This can all be controlled/viewed from anywhere in the world via the cloud based portal that is created for every customer.

Benefits of the CoolPro EM System:

- HVAC System monitoring 24/7/365 from Phone or PC

- Ensure Proper Set-Back Settings are Maintained

- Automatic Maintenance Notifications can be Set

- Minimize Energy Loss during UN-OCCUPIED Time Periods

- Energy Consumption Monitoring an Option

- Reduced Energy Consumption

EFFICIENT LIGHTING

The Lighting Industry consists of a million piece puzzle. The LED revolution has begun, but T8 and T5HO Fluorescent technology is still alive and kicking. When lighting is part of the Total Energy Optimization System that is proposed for a facility, we always consider two things first and foremost:

1. The resulting look of the facility.

2. Energy Savings.

The lighting package might be a full overhaul of the lighting system in your facility, or it might be pieces that may have been left out from a lighting project that was completed previously, either way, TEC will design a lighting package that will not only look good, but provide as much energy savings as possible without compromising the overall look. Light is essential for every facility in order to operate. TEC takes a serious stance with lighting as you only get once chance to get it right!

FULL LED Strip Fixture Retrofit:

- 50% Reduction in Energy Consumption

- 10 Year Warranty

- More Light Output

Open Case Cooler LED Retrofit:

- 32% Reduction in Energy Consumption

- More Light Output

FULL LED Retrofit INDOOR and OUTDOOR:

- 50% Overall Energy Savings

- More Light Output

FULL LED OUTDOOR Retrofit:

- 50% Energy Savings

- 10 Year Warranty

- More Light Output

FULL LED OUTDOOR RETROFIT:

- 70% Reduced Energy Consumption

- More Light Output

Our CUSTOM LED Retrofit for Outdoor/Parking Lot Lighting:

- DLC Listed

- 251W LED for 1000W Metal Halide

- 10 Year Warranty!

- Qualifies for Rebates

- 77% Energy Savings with MORE lumen output

If the existing fixtures are in good shape, why spend the money to replace the entire fixtures? We can design an LED retrofit kit for just about any existing fixtures for a LOT LESS money than replacing with new fixtures.

FACILITY GROUNDING / ELECTRICAL SYSTEM MAINTENANCE

Proper Electrical Grounding is one of the MOST IMPORTANT components of the system offered by Total Energy Concepts. More than 70% of all facilities in today’s world are not grounded properly. Not only is a proper ground essential for the efficient operation of electrical equipment within your facility’s electrical system, it’s also essential for the TEC Energy Optimization System to function properly. The National Electrical Code recommends the ground resistance from the facility to a ground rod, or earth ground to be 25 Ohms or less…we recommend all of our installs have a ground resistance of 10 Ohms or less. If your facility doesn’t have an adequate ground, we will provide one…whether we have to improve what you already have, or implement a completely new ground system…either way, before we sign off an installation, there will be an adequate ground system at your facility.

Panel, or Electrical System Maintenance is another aspect of every electrical system that is overlooked. If we think back to the water hose analogy….and think of electrical wires in a panel as water hoses…the water would come into the panel, through the breaker, down the wires to the equipment where it is used…and then back to the panel. If the screws were loose at the connections…there would be water leaking all over the place…EXACTLY! The same thing can happen within electrical systems that are not in tip-top shape. Loose screws, or poor conductivity can cause equipment malfunctions, excess energy consumption, and even safety related issues. With every system we install….we ensure that all of the screws are tight and there is good conductivity in each and every panel that we have open to ensure the system we install provides the best results after installation.